Our Products

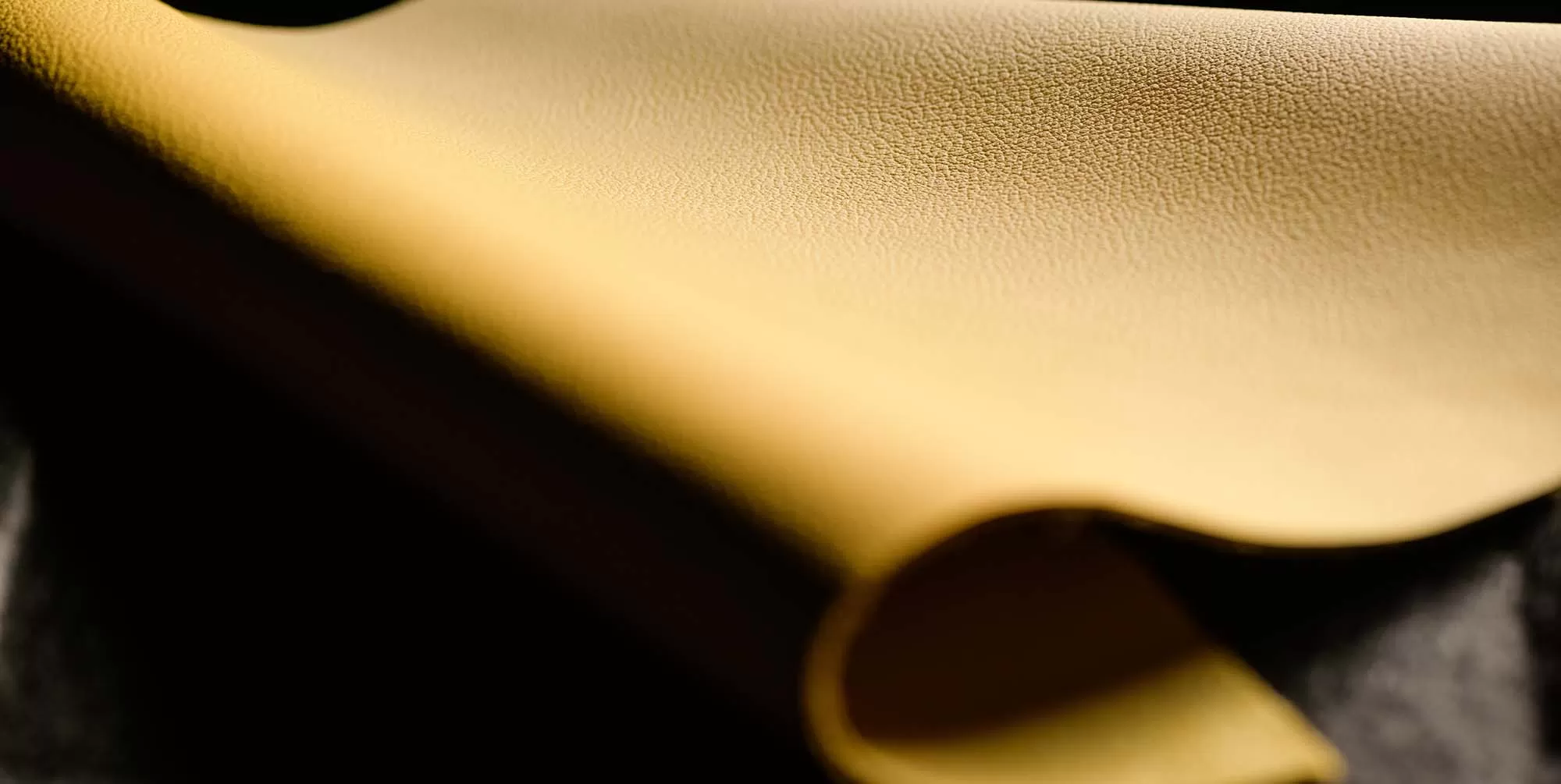

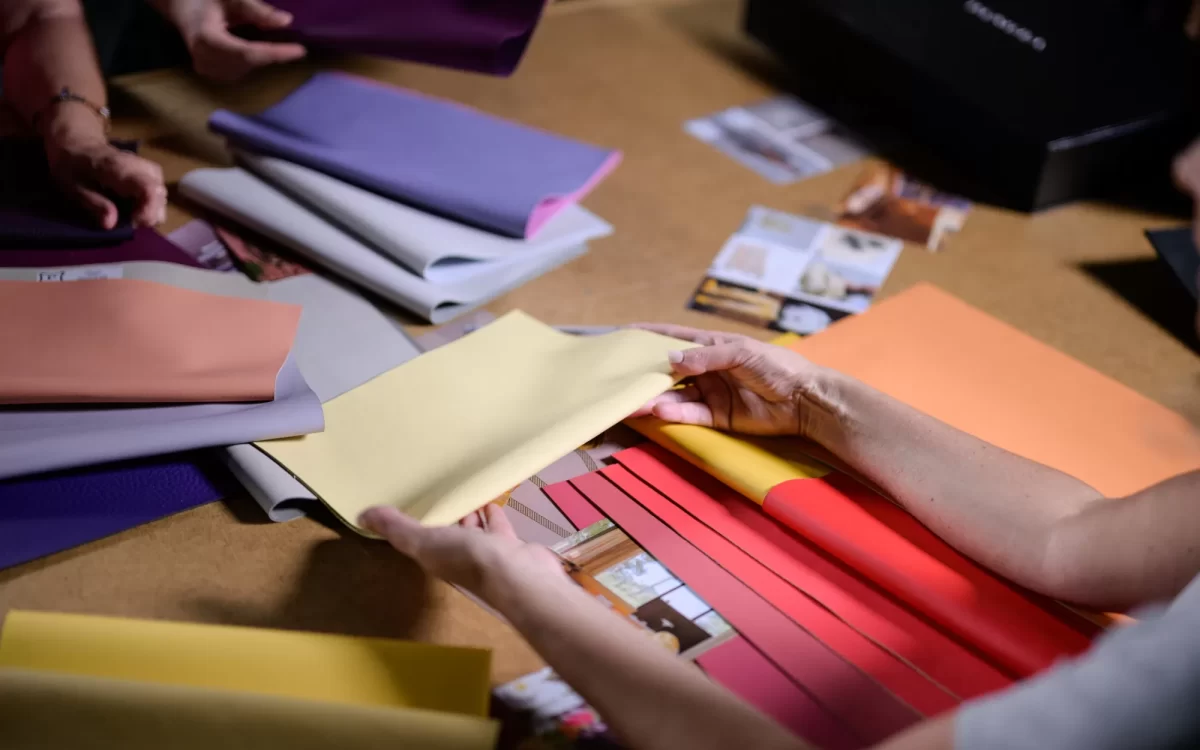

Our product development and design teams create custom colors, haptics and performance treatments unique to each customer. We quickly and seamlessly provide working prototypes for automotive interiors whether it be the most modern, luxury electric vehicle or a rugged, award-winning SUV. Leather is a universal material for consumers concerned about sustainability, performance and hand-crafted beauty.

Introducing the Pangea Family of Advanced Products

At Pangea, our mission is to take what nature has created and preserve it. Enhance it. Make it useful and beautiful. Using proven tanning and finishing processes, followed by our distinctive enhancement techniques, we have crafted a stunning new range of automotive leather solutions.

Enrichments

Leather enrichments help showcase the personality of a vehicle brand. Welding, quilting and perforation can all offer subtle – or dramatic – looks and dimension to the vehicle’s leather interior, while embracing other design details such as tone or contrast. Additionally, supporting our customer and seat development teams from concept through production helps to minimize cost and time – and maximize design impact.